⏪back

| Project Name | : | Beer Tunnel Pasturization Process Automation. |

| Client | : | Carlsberg - SANGAREDDY. |

| Controller | : | Siemens S7-300 CPU 315C-2PN/DP |

| Communication Used | : | Ethernet,Profibus, MPI |

| Third Party Devices | : | No. |

| SCADA | : | WinCC V7.4 |

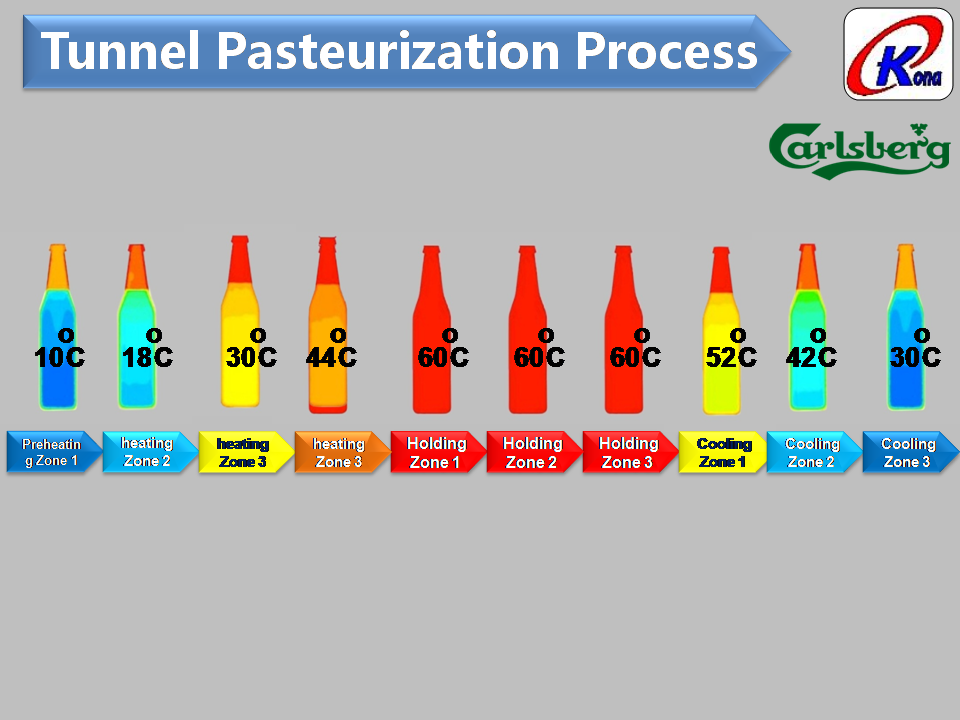

| Project Description | : | Designed to optimize and automate the pasteurization process for beer. It precisely controls temperature and time parameters to ensure product quality, safety, and shelf life. The system leverages advanced sensors, real-time monitoring, and automated adjustments to maintain consistent pasteurization, reducing manual intervention and energy consumption while meeting industry standards.Pasteurization Unit (PU)= t x 1.393 Exponent(T-60) where 't' = Time in Minutes, where 'T' = Holding Temperature. |